Detecting High Voltage PD and Corona Discharge

Partial discharge (PD) can cause a number of very serious and expensive problems, from catastrophic equipment failure to lethal arc flashes. The only way to stop this from happening is to regularly inspect and maintain the equipment properly. However, when the prevailing methods of detection range from wearing headphones and listening for very faint sounds to squinting at small screens to locate issues, all the while inside hazard zones, it’s often a task that gets neglected.

Placing technicians into dangerous situations has often been reason enough to forgo preventative maintenance routines on insulators, transformers, high voltage powerlines, switch gears, and more. Instead it is common to simply replace damaged units when they eventually fail, carrying the cost of these unnecessary losses and their associated downtime.

Its inefficient and costly, and it doesn’t need to be.

Solutions

Early detection is always key in extending the lifespan of equipment. Significant problems often begin as minor ones which are typically repairable at these early stages. Without regular and thorough preventative maintenance routines these problems will often remain unnoticed until they become too large to fix.

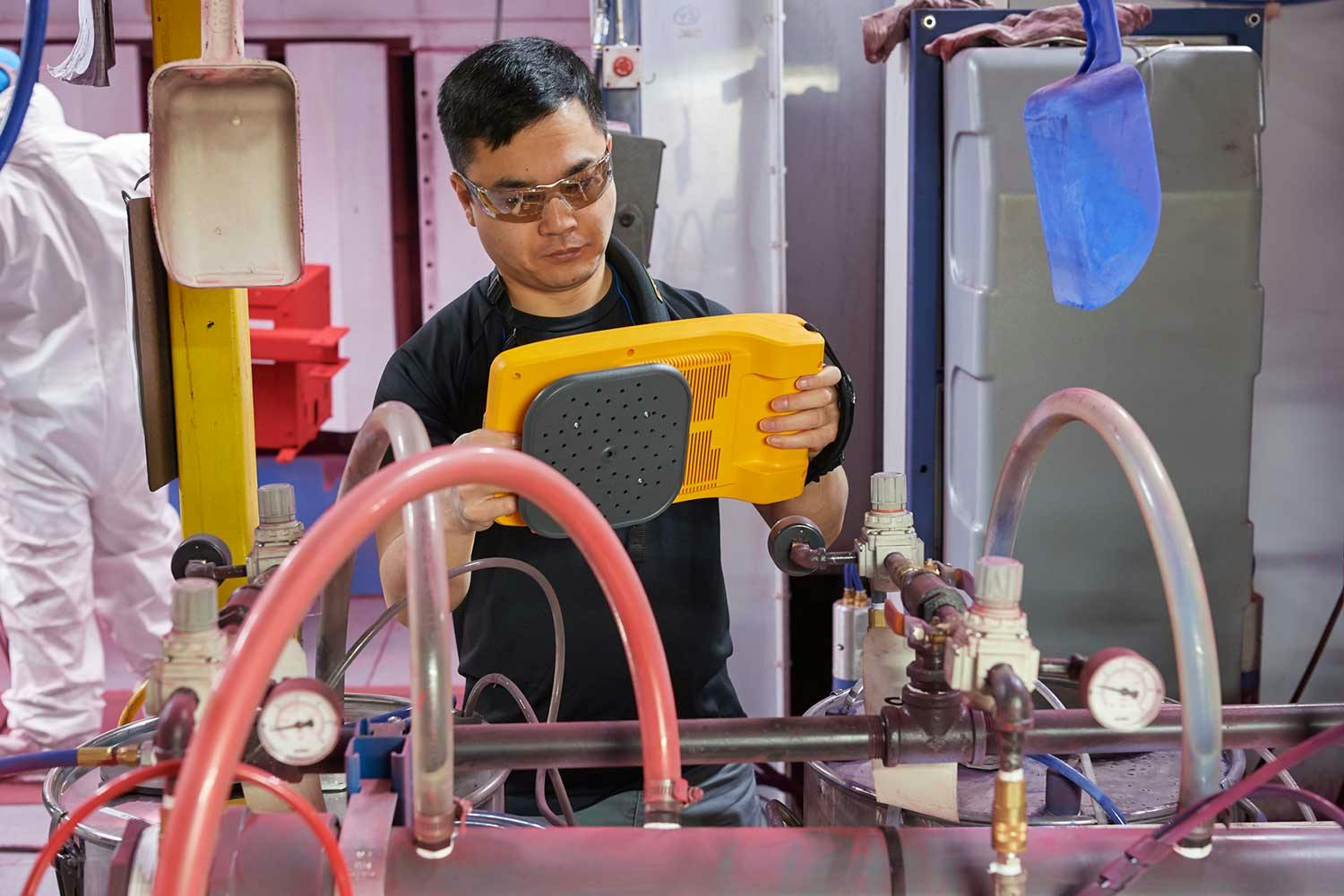

With the Fluke ii915 Precision Acoustic Imager preventative maintenance routines are finally feasible and within reach, ready for you to extend the life of your equipment and prevent unexpected downtime.

Traditional Solutions

- Require proximity to hazardous area

- Point-by-point manual testing

- Manual reporting

With the Fluke ii915

- Safer: remotely provides visual location of PD points

- Faster scanning and pinpointing faulty slots

- Provides rich data for analysis

- Captures pictures for easy visual reporting

Early PD detection

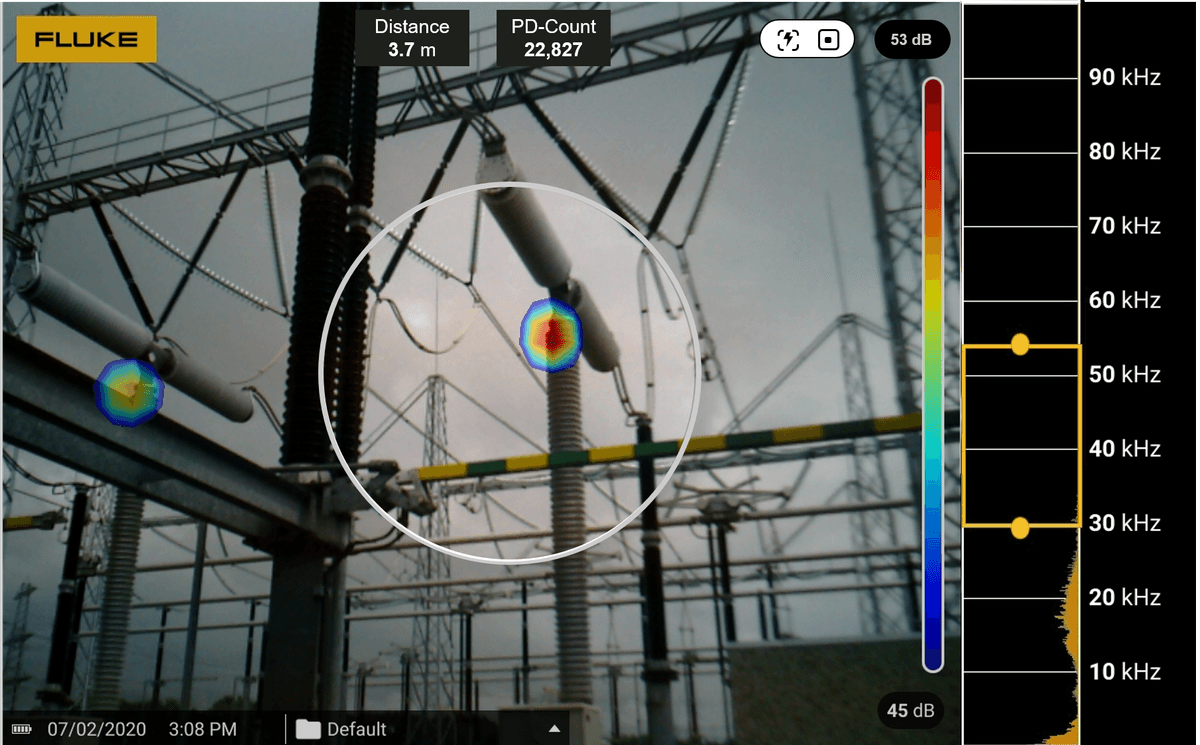

The higher frequency range of the Fluke ii915 allows for the earlier detection of PD issues to facilitate early maintenance planning. Scientific research* has shown that the frequency of acoustic emission signals (across multiple types of partial discharge) typically ranges between 20 kHz and 110 kHz. Therefore, the additional frequency capability of the Fluke ii915 is useful for PD detection.

In addition, this same research has shown that ‘surface discharge transferred 95% of the acoustic wave energy in the band between 48 kHz and 100 kHz. Frequency centroid was 78.6 kHz and a peak frequency was 68.3 kHz’.

*Sikorski, W. (2019). Development of Acoustic Emission Sensor Optimized for Partial Discharge Monitoring in Power Transformers. Sensors, 19(8), 1865.

Analyse PD and generate reports instantly

Built into each Fluke ii915 is a PDQ Mode that allows you to track the severity of detected discharges with the estimated pulse counting feature – PD Count. You can then use this information to easily generate detailed reports with PD analysis. This reporting tool uses an advanced AI algorithm to classify different types of partial discharge such as external discharge (electric arc/corona discharge), internal discharge, tracking (surface) discharge, and other discharges. You can also generate discharge analysis graphs displaying the magnitude of PD as a function of the phase degrees of the chosen supply voltage frequency. These reporting tool features enable you to save even more time and disseminate information between your technicians, maintenance team, and managers with unparalleled ease.

Unparalleled Safety

Using a revolutionary new technology to isolate the distinct sound frequencies of partial discharge from an incredibly safe distance of up to 120 metres away, technicians can now conduct comprehensive inspections without any concern for their wellbeing hovering over them. From the safety of the ground well outside the hazard zone technicians can now comfortably point the device at the subject and immediately see where partial discharge is occurring before placing themselves into potentially dangerous situations.

Easy and efficient

The ii915 utilises a unique SoundMap technology to visually display detected sound frequencies on screen. By doing so potential partial discharge issues are easy to spot and record. As such, inspections using these tools will cut down the time it takes to complete maintenance routines to a fraction of their former selves.

Due the device’s nature, the Fluke ii915 can even detect the reflections of sounds, meaning that you can even identify partial discharge occurring without line of sight, such as within closed cabinets. High up and hard-to-reach places are also within reach for a technician armed with a Fluke ii915, meaning inspections can be more comprehensive than ever while simultaneously being faster than traditional methods.

Minimal training required

If it looks like the Fluke ii915 is easy to use, that’s because it is. The Fluke ii915 is fundamentally designed so that anyone can use it with little to no training. Simply turn on the device with one button, select your frequency range, and start scanning around the area to immediately look for partial discharge. Once you find a concerning image of a sound you can take a photo or video to be used later after you have added any text annotations as desired. Check it out for yourself in the 360° Virtual Demo.